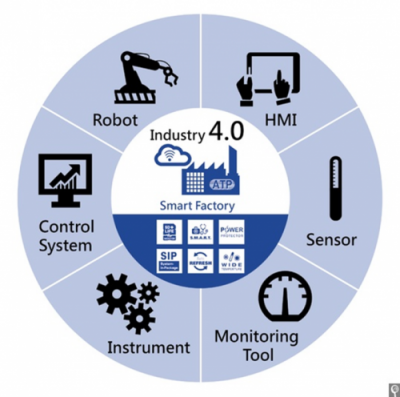

The term Industry 4.0 refers to smart factories, that is to say the transformation of manufacturing production through the use of technologies defined as intelligent and enabling, capable of fully exploiting the characteristics of artificial intelligence, interconnection and machine-to-human interaction.

This trend of technological renewal is also part of the Government's National Industry 4.0 Plan, presented in September 2016, which aims at facilitating investments in innovation by Italian companies. In April 2017 the decree law n ° 50/2017 was issued concerning tax benefits which governs government incentives for industry 4.0 and defines the eligible assets by dividing them into: assets that enjoy Super Depreciation and assets that enjoy iper amortization

The Industry 4.0 paradigm consists of 3 parts:

Smart production: new production technologies that create collaboration between all the elements present in the production or collaboration between operator, machines and tools.

Smart services: all the "IT infrastructures" and techniques that allow systems integration; but also all the structures that allow, in a collaborative way, to integrate the companies (supplier - customer) between them and with the external structures (roads, hubs, waste management, etc.)

Smart energy: all this always with a keen eye on energy consumption, creating more performing systems and reducing energy waste.

The challenge for companies is to respond quickly to these changes, seizing the opportunity for growth through a strategic innovation approach to business models.

We help companies to become BUSINESSES 4.0 by choosing the most suitable enabling technologies for specific needs.

We bring together machines, systems and materials thanks to new technologies to improve business processes.

We help companies to create a service economy in manufacturing, revolutionizing technologies, business and a market approach.

Our twenty years of experience in the manufacturing sector has allowed us to identify specific business cases, focusing on process management, for which we study and design, together with our customers, the most suitable technological solutions for specific business needs. Our specialized team will help in the business transformation process with a structured approach.

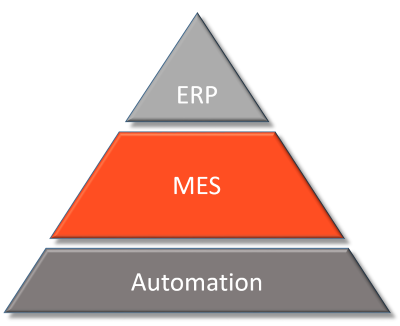

The consultancy and support of Twingroup aim to favor the definition of new business models for customers, drawing with them the path of convergence between business and technology. The starting point is to establish the level of maturity achieved in the management and digitization of the business, and then set up the business transformation project from a 4.0 perspective, with a focus on:

Contact us for more information